The company's metallographic laboratory has completed its upgrade.

Classification:

Company News

Author:

Source:

Release time:

2025/03/05

Information Summary:

To effectively analyze the comprehensive performance of the metal materials of our company's products, further improve product quality, and enhance our company's market competitiveness, the company has recently completed the upgrade of the metallographic laboratory.

To effectively analyze the comprehensive performance of the metal materials of our company's products, further enhance product quality, and strengthen our company's market competitiveness, the company has recently completed the upgrade of the metallographic laboratory.

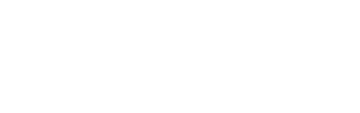

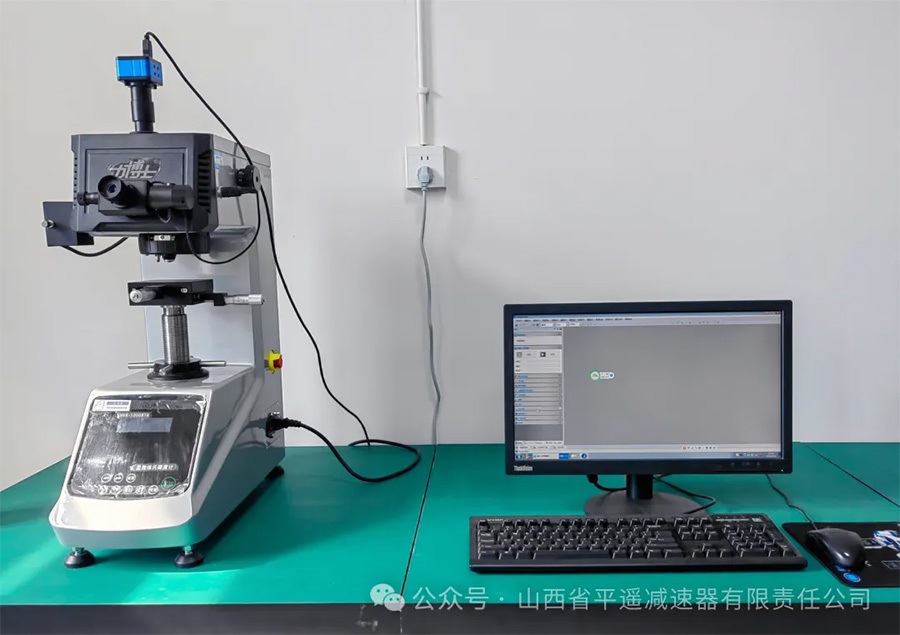

The metallographic laboratory mainly consists of two core areas: the sample preparation area and the observation area. The sample preparation area is equipped with cutting machines, embedding machines, pre-grinders, and polishers to ensure the accuracy and consistency during the sample preparation process. The observation area is equipped with a 1000x metallographic microscope and a 400x micro Vickers hardness tester, among other testing instruments. These devices provide important testing data for our company to analyze the internal microstructure, grain morphology, and key performance indicators such as hardness of metal materials, while also providing a basis and guarantee for our company to continuously improve the comprehensive performance of metal materials. Metallographic testing is an important means of evaluating the performance of metal materials. After a series of fine treatments such as slicing, grinding, and polishing, the internal structure is observed and analyzed in detail under a microscope, allowing for an accurate assessment of the material's grain size, uniformity, inclusions content, and mechanical performance. This testing method not only helps determine whether the material meets the preset technical standards but also provides a scientific basis for improving production processes and optimizing production, thereby enhancing the reliability and service life of the products. For us, the establishment of the metallographic laboratory will greatly enhance our company's work efficiency in quality control of metal materials. Under the leadership of Minister Yan from the technical department, the technical team will continuously strengthen their learning and practice of professional skills, strictly adhere to the relevant national standards and industry norms for metallographic testing, and ensure that every testing data is accurate and reliable. At the same time, the company will continue to pay attention to the development trends of metallographic testing technology at home and abroad, actively introduce cutting-edge technologies and concepts, provide more professional services to our customers, and strive to achieve a new leap in customer satisfaction.

Key words:

Mining reducer

Xinkai

Previous Page

Related News

Congratulations to the Taiyuan R&D and Promotion Center on its launch

2025-03-14

On March 5th, the Pingyao Reducer Co., Ltd. of Shanxi Province officially established and launched its Taiyuan Research and Development Center. General Manager Liu Changsheng presided over the establishment ceremony, which began with the singing of "Sing My Motherland": "The five-star red flag flutters in the wind, the triumphant song is so resounding..." This inspiring melody is the company's firm vow to forge ahead bravely on its new journey! "The long and arduous road is like iron, but now we start anew." The establishment of the Taiyuan Research and Development Center is a significant milestone in the company's History, marking the beginning of a new journey.